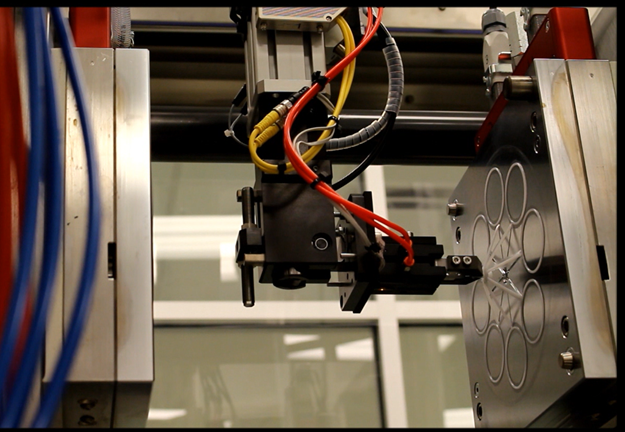

Injection molding is ideally suited for creating shapes such as drug-eluting ear tubes, punctal plugs, and pessaries from both silicones and thermoplastics. In addition to low cost, quick-turn prototype molds, high-precision (micron tolerances), stainless steel molds are designed and fabricated in house. ProMed has developed innovative approaches for mixing of different APIs and polymers with excellent content uniformity and low waste. Parts in sizes from milligrams to 10g can be manufactured in small quantities to tens of thousands of units per batch from molding machines in size from 10 to 340 tons (compression force).